EM ERITO CAPPING MACHINES

The widest range of capping machines on the market with Twist Off (TO) and PT closures for Baby Food.

EMERITO manufactures the widest range of Twist-Off and PT closing systems in the national and international market, from small production runs to high speed production, with the same guarantee and reliability.

We're technology

Why choose our capping machines?

Fully adaptable

To all glass jar formats available on the market, provided that the container is rigid and has a Twist Off or PT type closure system.

ACT System (Antislip Chain Traction)

Sealing guarantee when working with containers impregnated with oil or slippery substances.

Configurable lids

Cap feeder with options for correct positioning of each cap by technical or pneumatic means. Versatility for all existing Twist Off and PT cap sizes.

Automatic format changeover

Option designed exclusively by our team, which allows the capping machines to adapt to different formats of jars in a very simple and automated way, including a PLC with its own software and touch screen, all fully integrated into the control panel. The most extreme format changeover is done in 3:30 minutes.

Safety vacuum

All our EMERITO capping machines are equipped with lid pre-heating, lid injection, sweeping and steam extraction systems to facilitate the creation of a safety vacuum.

High quality stainless steel

All our capping machines are manufactured in high quality, food grade stainless steel, mainly AISI 304 and AISI 316. The complementary and commercial components are of the most prestigious and well-known brands in the world market.

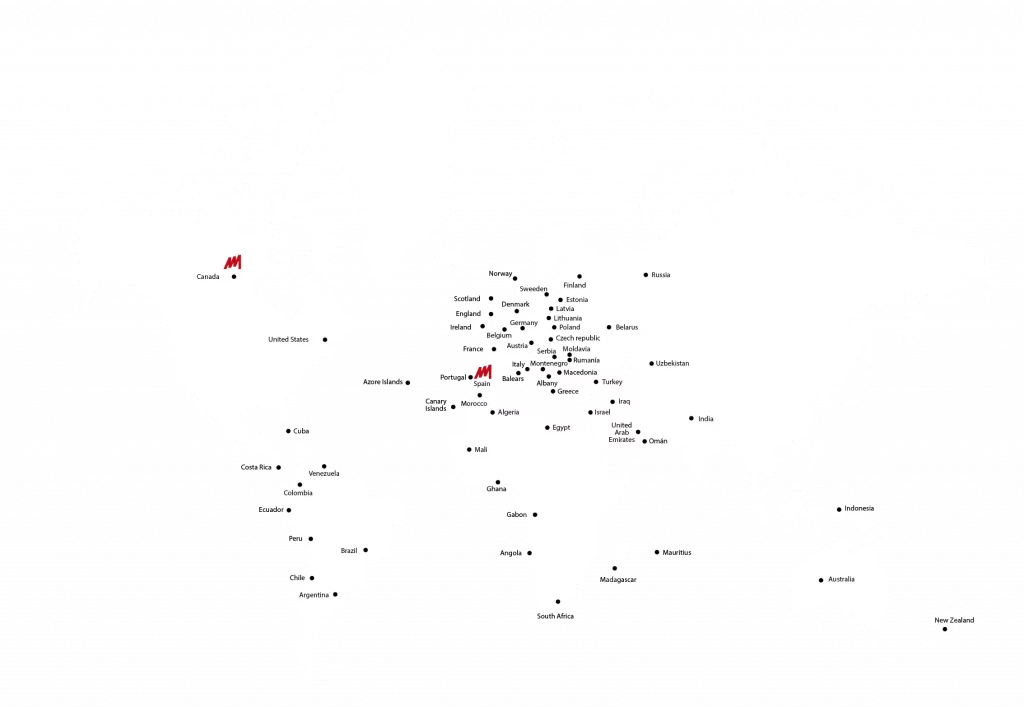

Our capping machines are already installed and operating successfully in more than 60 countries.

SEE OUR FULL RANGE OF CAPPING MACHINES

Semi-automatic capping machine with pneumatic system.

Different heads adjustable to different sizes of lids.

Adjustable container clamping system for all jar formats, which ensures the perfect clamping of the container prior to capping.

- Low Productions

- Semiautomatic

Semi-automatic closing machine with pneumatic system. Twist Off type closures.

Different closing heads available, adjustable in sizes and types of lids.

Container anchoring system, by means of tracks, augers and positioning stars, valid for all formats of jars by replacing the corresponding parts.

Closes up to 20 containers per minute.

- Low Productions

- Automatic

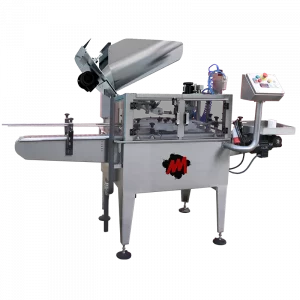

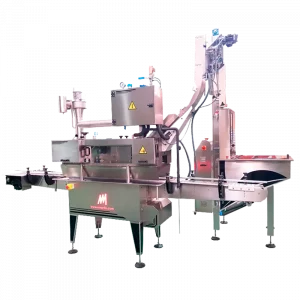

Automatic capping machine. Twist Off and PT type closures.

Equipment valid for a wide range of containers and caps to be used. It only requires simple and intuitive adjustments without any change of parts.

Adjustments for different container heights.

Closes up to 70 containers per minute.

- Medium Productions

- Automatic

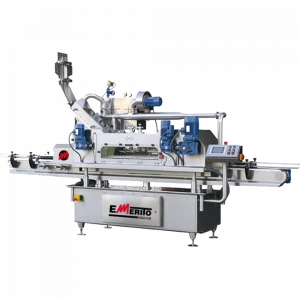

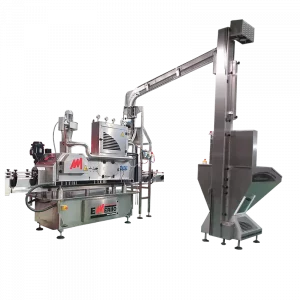

Automatic linear capping machine. Twist Off and PT type closures.

Equipment valid for all ranges available in the world food market, both in containers and closures to be used. It only requires simple and intuitive adjustments without any change of parts.

Closes up to 70 containers per minute.

- Medium Productions

- Automatic

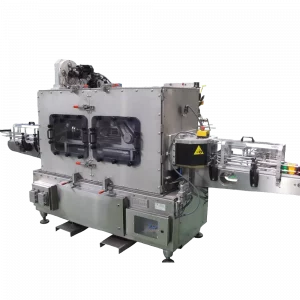

Linear automatic capping machine. Twist Off and PT type closing.

Motorised format changeover for different container heights in its standard version.

There is an option for automated container format changeover, the resulting model being the Emerito 2.8 SP.

Closes up to 130 containers per minute.

- Medium-High Productions

- Motorised Format Chageover

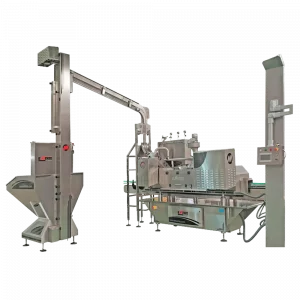

Automatic linear capping machine. Twist Off and PT type closers.

It has an option for automated container format changes, the resulting model is the Emerito 2.8 SM machine.

Closes up to 200 containers per minute.

- Medium-High Productions

- Automatic Format Changeover

- High Productions

- Automatic Format Changeover

Automatic linear capping machine, Twist Off and PT type closures.

Requires tooling changeover for lid and bottle format changes.

Maximum production: 25 containers/minute.

- Low Productions

- Bottles Without Humid Atmosphere

Automatic linear capping machine, Twist Off and PT type sealing.

It includes as standard the option to carry out the changes of packaging formats in an automated way.

Maximum production 600 containers/minute.

- Super High Production

- Automatic Format Changeover