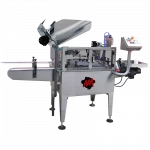

Emerito 0.8 Capper Machine

-

Types Of Closure

Twist-Off & PT

-

Lids

Diameter: from TO27 to T82

Height: up to 18 mm (DTO) -

Containers

Diameter: from 30 mm to 106 mm

Height: from 40 mm to 260 mm -

Container Format Changeover

Requires alternative tooling

Ideal for small producers, entrepreneurs, laboratories or test lines.

Automatic glass bottle capper suitable for laboratory work or for producers who handle few formats of bottles and lids with Twist Off and PT system. In the case of PET bottles with Twist Off lids, the quality of the work of this equipment will depend directly on the quality of the PET format to be used in it.

This equipment works by means of a rotary transport system of containers inside and with a closing head adapted to the corresponding cap diameter using the so-called BC-“Balaced Capping” technology.

Optionally, it incorporates a steam management system that we receive from the boiler already existing in the factory, to facilitate the generation of a safety vacuum by injecting it into the head space of the container prior to closure. This steam management system also includes the corresponding module for the extraction of excess steam during the capping process.

The production/closing capacity of our Emerito 0.8 seamer is a maximum of 20 containers per minute and container and lid format changes are carried out, albeit easily, by means of alternative tooling.